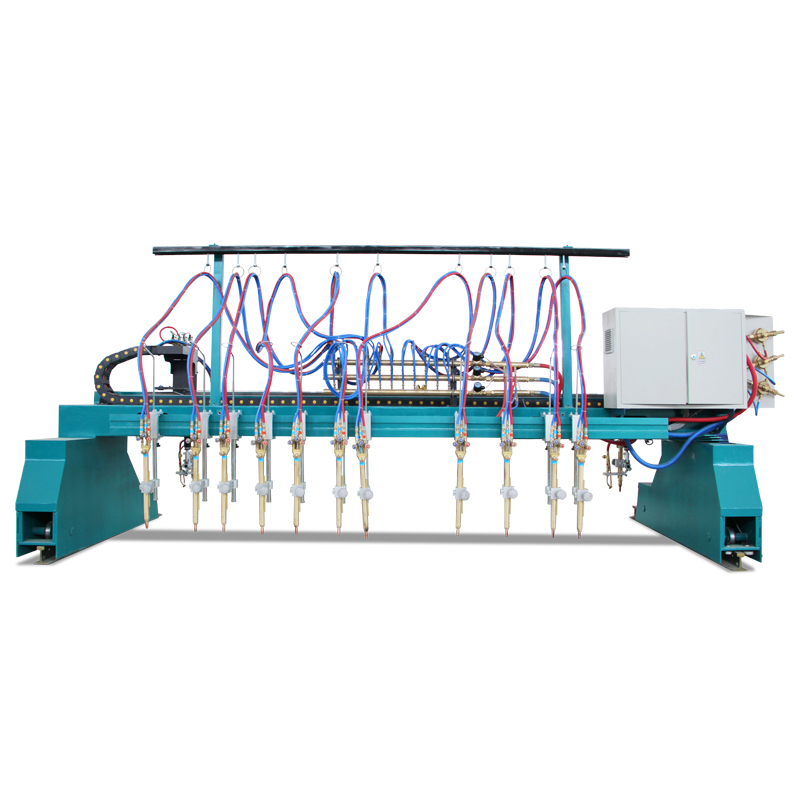

It is also called oxygen cutting, which uses a preheating flame to heat a certain point on the surface of the steel plate to the ignition point (about 1000 ℃), and then fills the ignition point with high-pressure oxygen to support combustion, so that the steel plate is burned to form a cutting method. Its applications are mainly limited to the cutting of carbon steel and large thickness plates, and it will gradually be replaced by plasma cutting in the cutting of medium and thin carbon steel plates.

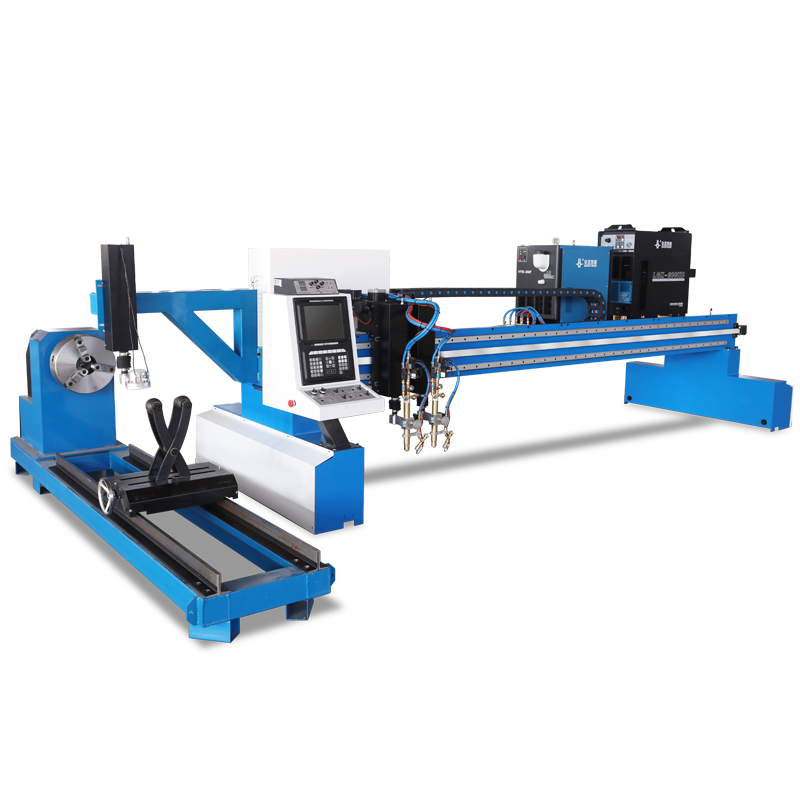

Manual cutting (can't control the route and speed, low cutting accuracy) - trolley cutting (can only walk in a straight line) - copy cutting (it is troublesome to make models, can't cut continuously, can't cut multiple graphics, can't cut combined graphics) - CNC cutting

Contact: Alex Wang

Tel / WhatsApp:

0086-13153107480

Email: sales@yomi-china.com

Add: 14 Brussels Road , Spartan Kempton Park,Gauteng South Africa 1619